The press brake punches of the working areas is 45±2° HRC. We use high-quality local materials that meet the best metallurgical standards and conditions.

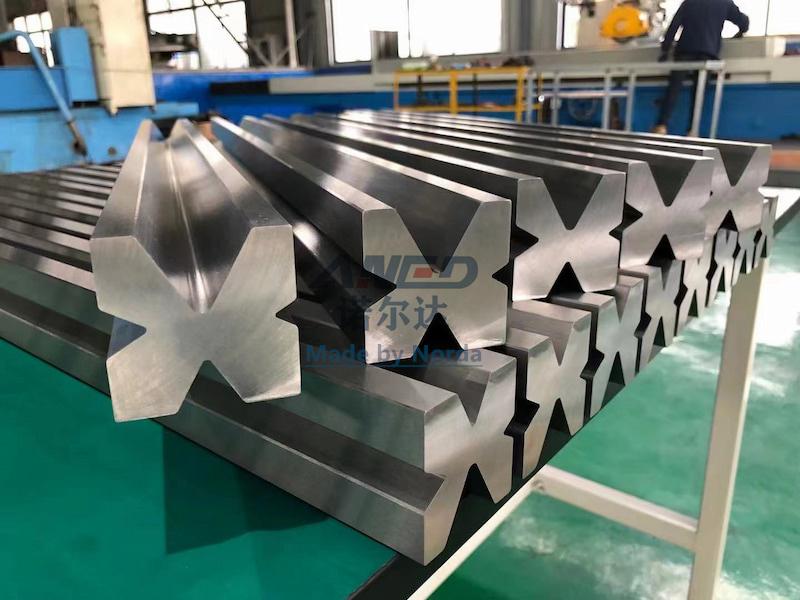

Tool System :

European LVD SystemAngle :

26°Radius :

R1mmEffective Height :

180mmMaximum load :

500kN/mMaterial :

42CrMo

Our press brake tools undergo an induction hardening process that provides maximum protection and hardness in the working areas where the tool comes into contact with the part during the bending process. The standard hardness of the working areas is 45±2° HRC (mainly the die shoulder and the punch tip). We use high-quality local materials that meet the best metallurgical standards and conditions.

▶ Optimal material

▶ 42 CrMo, tempered to 1100-1200 N/mm²

▶ Bending radius/intake radius hardened to 45±2° HRC

▶ Precision ground

▶ Guaranteed interchangeability and parallelism

▶ Tool marking with all technical information

Company advantages

Maanshan Norda Mold Manufacturing Co., Ltd. is a modern enterprise focusing on the research and development, production and sales of bending machine molds. It has 20+ years of experience, high-end precision production equipment and a professional technical team, as well as a strict production management system. Due to the continuous improvement of products, it has been widely trusted by many industries. After the development of the industry in recent years, there are currently more than 1,200 domestic and foreign cooperative customers, and the products are exported to Europe, America, Japan, Southeast Asia and other regions.

Material quality: The material of Norda's bending machine mold is selected from high-quality tool steel or other suitable materials to ensure the hardness, wear resistance and life of the mold.

Design and precision: The design of Norda's mold is in line with actual needs and has good precision and stability. The structure of the mold should be reasonable to achieve the required bending angle and shape.

Manufacturing process: The manufacturing process uses advanced technology and equipment to ensure the quality and precision of the mold. Norda has rich experience and technology to manufacture and process the mold as required.

After-sales service: Norda is a reputable and reliable supplier that can provide timely after-sales service and support. This includes technical consultation, repair and replacement of parts, etc.

Specification

| Maximum pressure resistance of mold (ton/m) | 250 | ||

| Flap center distance (mm) | 38 | ||

| Maximum thickness of bending plate (mm) | 6.0 | ||

| Shortest bending side length (mm) | 22.5 | ||

| Thickness of bending plate (mm) | 2.0 | 4.0 | 6.0 |

| Minimum bending angle (°) | 68 | 47 | 50 |

| Maximum bending outer radius (mm) | 13.9 | 11.9 | 9.9 |

| Minimum bending pressure (ton/m) | 7.0 | 34.0 |

90.0 |

Product Detail

FAQ

Here are some common questions and answers about bending machine dies:

Question 1: What is the life of a bending machine die?

Answer: The life of a bending machine die depends on several factors, including frequency of use, material strength and hardness, bending angle, etc. Under normal circumstances, after proper use and maintenance, the life of a bending machine die can reach tens of thousands of bending operations. However, it should be noted that if the material processed by the die is of poor quality, the bending force is too large, or the maintenance is improper, the life of the die may be shortened.

Question 2: How to choose a suitable bending machine die?

Answer: Choosing a suitable bending machine die requires consideration of several factors. First, it is necessary to determine the required bending angle and shape to determine the type and specification of the die. Secondly, it is necessary to understand the characteristics of the material to be processed, such as strength and hardness, to ensure that the die can withstand the required bending force. Finally, consider factors such as budget and production cycle to select a die that meets the needs.

Question 3: Do bending machine dies need to be maintained and maintained?

Answer: Yes, bending machine dies need to be maintained and maintained to extend their service life and ensure processing quality. Care and maintenance include regular cleaning, lubrication and checking the degree of wear of the mold. In addition, avoiding overuse and overload operation is also an important measure to protect the mold.

Question 4: Can the bending machine mold be repaired and modified?

Answer: Some damaged or worn bending machine molds can be repaired and refurbished to extend their service life. Repairs usually include repairing damaged parts, repairing surface wear, and re-grinding the blade. In terms of modification, some specific bending needs can be achieved by adjusting and modifying the mold to adapt to new processing requirements.

Question 5: How to determine the price of bending machine molds?

Answer: The price of bending machine molds is affected by many factors, including mold materials, complexity, size, and customization requirements. Common standard molds are usually cheaper, while special customized molds are more expensive. It is best to provide detailed needs and requirements to the bending machine mold manufacturer to obtain an accurate quotation.

Why Choose Us

Reference process for cooperation with Norda Mold:

Because we meet all the above conditions. We can provide high-quality bending machine tools that meet all your requirements and help you get accurate and consistent results.

Maanshan Norda Mold Manufacturing Co., Ltd. is a modern enterprise focusing on the research and development, production and sales of bending machine molds. It has 20+ years of experience, high-end precision production equipment and a professional technical team, as well as a strict production management system. Due to the continuous improvement of products, it has been widely trusted by many industries. After the development of the industry in recent years, there are currently more than 1,200 domestic and foreign cooperative customers, and the products are exported to Europe, America, Japan, Southeast Asia and other regions.

Please Read On, Stay Posted, Subscribe, And We Welcome You To Tell Us What You Think.

Copyright @ 2025 Maanshan Norda CNC Mold Manufacturer Co., Ltd All Rights Reserved.

Sitemap

/

Blog

/

Xml

/

Privacy Policy

Network Supported

Network Supported